TECHNICAL INFORMATION

Provides technical information related to products by AQUOSYS.

HOME

TECHNICAL INFORMATION

DAF

HELIFLOT™: Innovation of Dissolved Air Flotation

- 1. Overview of the general Dissolved Air Flotation (DAF):

- DAF is a water treatment technology that purifies water by removing suspended matter through the use of fine bubbles from dissolved air.

Advantages and disadvantages of DAF compare to Sedimentation

| Advantages | Disadvantages |

|---|---|

|

• High speed treatment • Produces thick sludge • Shorter flocculation detention time • Shorter start-up lead time • Compact facilities required • Omissible for recovered sludge thickener |

• Requires more complex facilities • Consumes more electrical power • Unsuitable for highly silt-laden water |

- 2. Introduction of HELIFLOT™

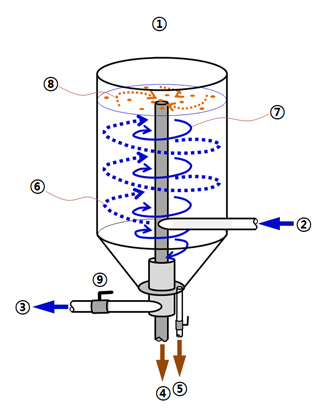

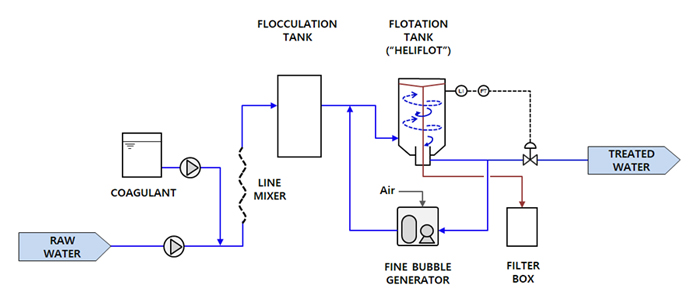

- HELIFLOT™ is a cylindrical DAF unit that runs with helical flows, developed by Aquosys.

- Raw water and fine bubbles are fed into the flotation tank (①) by an inflow pipe connected to the tangent (②).

- Suspended materials form flocs with fine bubbles, creating a helical flow with the water to move upwards (⑥) and gather around the center of the water surface (⑧). The flocs are discharged out of the flotation tank through a scum outflow pipe (④).

- The treated water then creates another helical flow to move downward (⑦) inside of the helical flow moving upwards.

They are then discharged continuously out of a treated water outflow pipe (③). - The water level of the flotation tank is controlled with a flow control valve (⑨) suitable for scum control.

- Silt or something dense moves to an outer position on the flotation tank by centrifugal force. It settles down to the conical bottom and then evacuates to the outside periodically (⑤).

- 3. A suspended material removal process by the HELIFLOT™

- Simple and high efficiency

- 4. Applicable wide range of contaminated water treatment

- From very low concentrations of algae water to high concentrations of settled sludge:

Algae Water Treatment

Sludge Concentration

- 5. Comparison with HELIFLOT™ to the conventional DAF

| Conventional DAF | HELIFLOT™ |

|---|---|

|

• More complex facilities required: – Scum skimmer, subnatant remover and (settling lamella plates) needed. • Weak on load fluctuation • Unsuitable for treating high silt-laden water. • Compact facilities required: – Detention time(min): Floating: 20 ~ 30 Conglomeration: 15 ~ 20 • Chemical consumption(ppm): – Organics: 5 ~ 10 – Inorganics: 10 ~ 30 (normally both chemical required) • Electric consumption(kWh/㎥): – 0.08 ~0.12 (Depends on the capacity) |

• Simplified facilities: – No scum skimmer, subnatant remover or settling lamella plates needed. • Stable on wide range of load fluctuation (even low flow rate or high solid content) • Capable for treating high silt-laden water. • More compact facilities required – Detention time(min): Floating : 8 ~ 10 Conglomeration : 0 ~ 15 • Chemical consumption(ppm): – Organics: 0.5 ~ 2 – Inorganics: 2 ~ 10 (available only one chemical used) • Electric consumption(kWh/㎥): – 0.06 ~0.10 (Depends on the capacity) |

- 6. Applications of HELIFLOT™:

- Tap water clarification (for pre-treatment or replacement of a flocculation and sedimentation process).

- Sewage and wastewater treatment (for pre-treatment or sludge thickening).

- Seawater desalination (for clarification).

- Industrial processes (for recovery of valuable effluences).

Scum on HELIFLOT

Removed scum

- 7. Standard Specifications

| HLF 100 | HLF 1000 | HLF 5000 | HLF 10000 | HLF 20000 | |

|---|---|---|---|---|---|

| Treatment rate (㎥/day) | 100 | 1000 | 5000 | 10000 | 20000 |

| Flotation tank volume (㎥) | 0.8 | 8 | 40 | 80 | 160 |

| Ground required (㎡) | 8 | 16 | 52 | 84 | 112 |

| Height (m) | 2.8 | 3.4 | 4.6 | 5.8 | 7.0 |

* Depending on the suspended solids in the water, the conglomeration tank may be required or omitted.

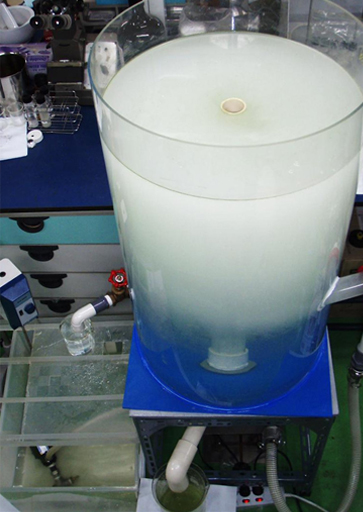

- 8. Examples of the HELIFLOT™:

2,400㎥ /day

16,000㎥ /day