TECHNICAL INFORMATION

Provides technical information related to products by AQUOSYS.

HOME

TECHNICAL INFORMATION

DEEPCTOR

HIGHLY COMPACT WASTEWATER TREATMENT PROCESS: DEEPACTOR™

A combination of

Bioreactors, working on deep water

Flocculation system, without an agitator

DAF system, with an innovative helical flow

Biofilter system, efficient and easy installation

Biological Treatment

A biological process is regarded as an useful and widely adaptable wastewater treatment system because of the low-running cost and the eco-friendly trait.

But, despite of the benefits, It has various problems to dissolved.

But, despite of the benefits, It has various problems to dissolved.

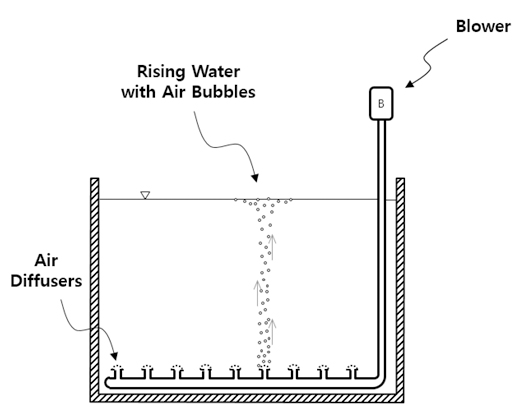

General Oxygen Feeding System

Aeration by Diffusers

What’s the Issue?

- Whereas the high BOD of the wastewater, the saturation solubility of the oxygen in water is very low as an example, 8.8ppm only at 20℃.

- It is very hard to exist air bubbles in water with stable, because the big gap of the specific gravities and the high surface tension of the water.

- General process of the oxygen feeding to a biological reactor is the bubbling method using a blower and diffuser.

- When the air bubbles fed into the water, the mixture rise up rapidly and most of the air waste out, and even the supersaturated oxygen water reduce down to saturation condition quickly.

- Especially, when the depth of the bioreactor deeper, the load of the blower is rise upped, eventually the depth of the bioreactor is limited to 5~6m.

- As the results, this system spent blown air, lies low dissolved oxygen conditions and requires wide ground area relatively.

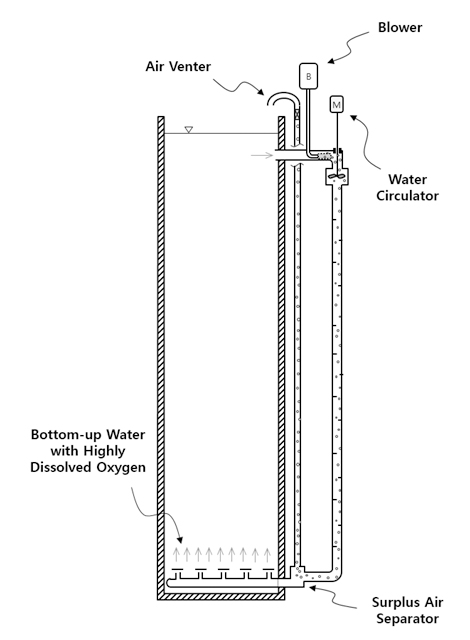

Solutions for the Oxygen Feeding

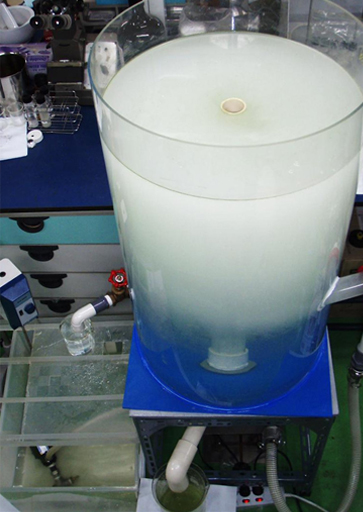

An oxygen feeding system; ‘DEEPFFECTOR™’ which developed AQUOSYS, constituted with a diffuser in low depth water-in line, a water circulator, a water circulating pipe, a surplus air separator and oxygen water discharge lines.

Oxygen Feeding System; DEEPFFECTOR™

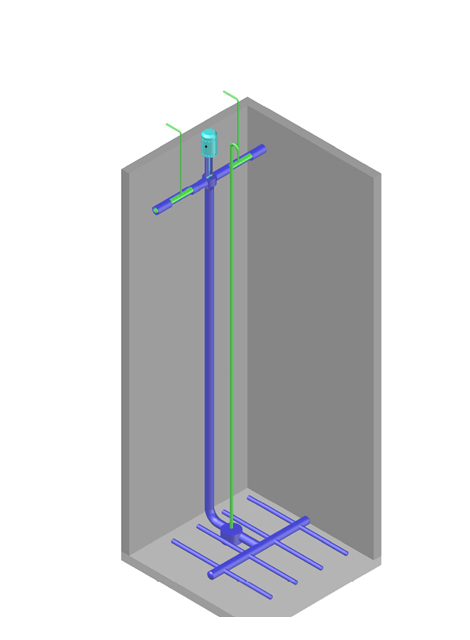

3D Diagram

Advantages of the ‘DEEPACTOR™’

- Because of the diffusers lay on shallow position, less energy required for air charging

- Because of the highly pressed oxygen water file-up to upwards, the water maintains

it’s saturated concentration → It makes biological activities rise up - Because of the deep depth reactor operation, can be reduce down the facilities site area

Advantages and disadvantages of DAF compare to Sedimentation

| Advantages | Disadvantages |

|---|---|

|

• High speed treatment • Produces thick sludge • Shorter flocculation detention time • Shorter start-up lead time • Compact facilities required • Omissible for recovered sludge thickener |

• Requires more complex facilities • Consumes more electrical power • Unsuitable for highly silt-laden water |

Wide application range of the HELIFLOT™:

From very low concentrations of algae water to high concentrations of settled sludge:

Algae Water Treatment

Sludge Concentration

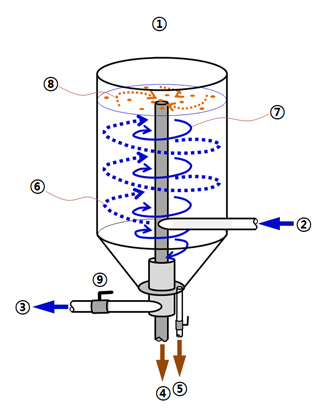

High-efficiency helical DAF; HELIFLOT™

- Suspended materials are lifted upwards with fine bubbles by a spiral flow in the cylindrical tank, and are automatically removed after they are collected at the center of the water surface.

- Float separation is completed within 10 minutes of residence time.

Capable for replacement of a sludge settling tank and omission of a concentration tank

- ① flotation tank

- ② inflow pipe

- ③ outflow pipe

- ④ scum outflow pipe

- ⑤ sediments out

- ⑥ upward helical flow

- ⑦ downward helical flow

- ⑧ gathering scum

- ⑨ flow control valve

A comparison with HELIFLOT™ to the conventional DAF

| Conventional DAF | HELIFLOT™ |

|---|---|

|

• More complex facilities required: – Scum skimmer, subnatant remover and (settling lamella plates) needed. • Weak on load fluctuation • Unsuitable for treating high silt-laden water. • Compact facilities required: – Detention time(min): Floating: 20 ~ 30 Conglomeration: 15 ~ 20 • Chemical consumption(ppm): – Organics: 5 ~ 10 – Inorganics: 10 ~ 30 (normally both chemical required) • Electric consumption(kWh/㎥): – 0.08 ~0.12 (Depends on the capacity) |

• Simplified facilities: – No scum skimmer, subnatant remover or settling lamella plates needed. • Stable on wide range of load fluctuation (even low flow rate or high solid content) • Capable for treating high silt-laden water. • More compact facilities required – Detention time(min): Floating : 8 ~ 10 Conglomeration : 0 ~ 15 • Chemical consumption(ppm): – Organics: 0.5 ~ 2 – Inorganics: 2 ~ 10 (available only one chemical used) • Electric consumption(kWh/㎥): – 0.06 ~0.10 (Depends on the capacity) |

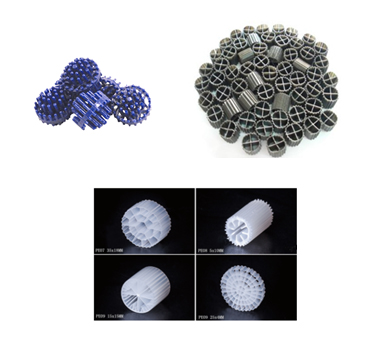

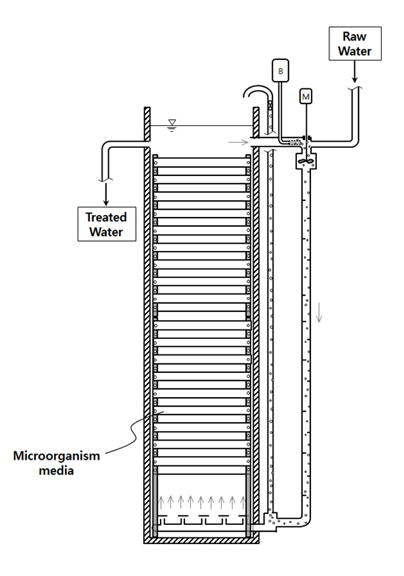

Assembly type microorganism media; AQUOSIEVE

Plate-like microorganism attachment plate and pillar spacing material are alternately stacked in multiple stages and fixed

Various Existing Media

Developed Media; AQUOSIEVE

AQUOSIEVE in a DEEPECTOR system

- Common biofilter treatments;

– Stable to variations in raw water load

– Unnecessary of sludge recycle system

– Low sludge generation

- Easy to make media

- Production of large products is possible

- Good fluidity and circulation of water inside and around the media

- Biomass material can act as a carbon source for nitrogen removal

- Bio-reaction is possible under high oxygen conditions

- Enables aerobic and anaerobic reactions in one reactor

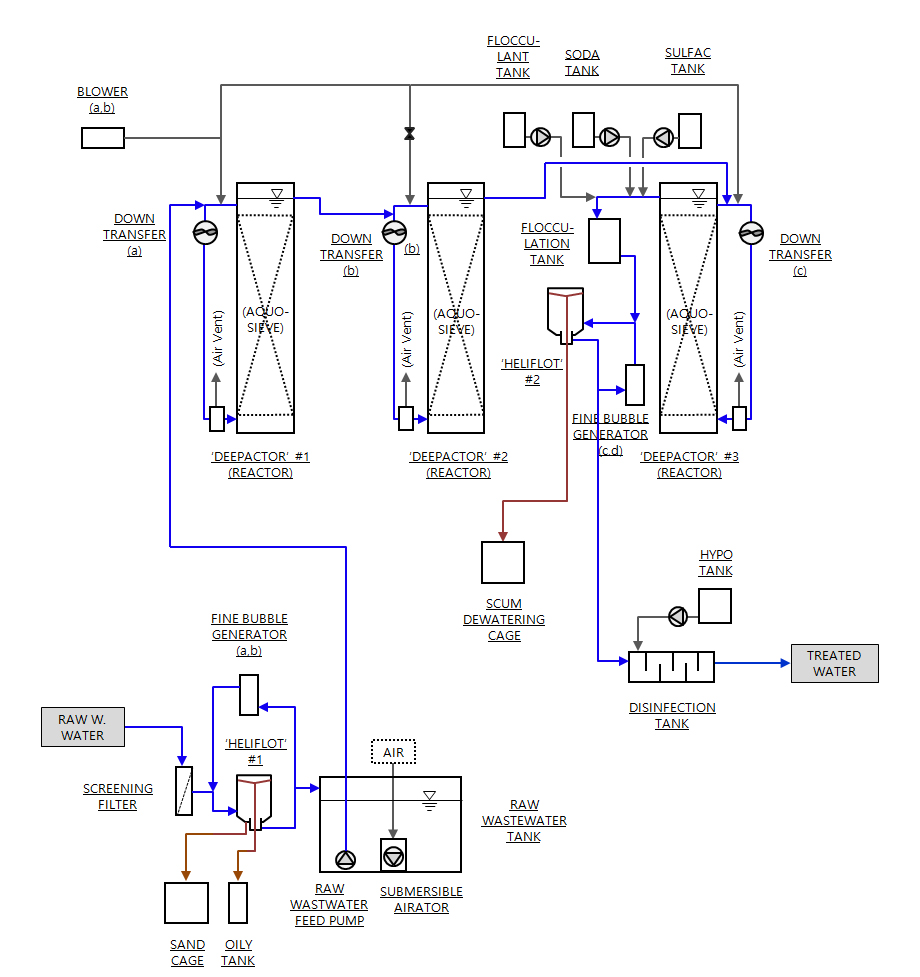

Schematic Process of a DEEPECTOR

PFD, WASTEWATER TREATMENT (1,000㎥ /day)

Korea Aquosys Co., Ltd. 2018.10.22 1/1

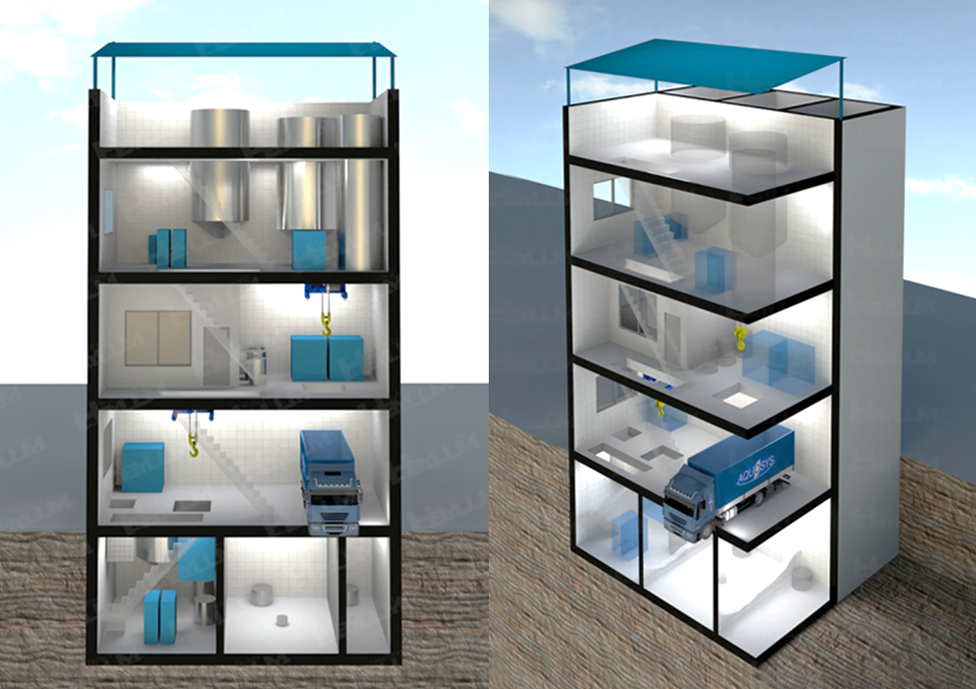

HIGHLY COMPACT WASTEWATER TREATMENT PROCESS (Layout)

Capacity: 1,000㎥ /day